Take the Next Step

Finding the right college means finding the right fit. See all that the College of Engineering and Computer Science has to offer by visiting campus.

Welcome to the Wright State University Materials Characterization Facility. Our purpose is to maintain the equipment, facilities, labs, and infrastructure required to study metallic, ceramic, polymeric, semiconductor, and composite materials at the micro- and nano-length scales. In addition to supporting researchers inside Wright State, we also work extensively with the surrounding Dayton manufacturing and STEM community.

Our metallography lab includes equipment specimen cutting, mounting, grinding, and polishing. We have several metallography and inspection microscopes.

Or mechanical testing facility includes up-to-date bulk hardness and Charpy toughness measurements, in addition to several Instron load frames with high-temperature capabilities.

Our capabilities are available for small projects on a collaborative basis. Larger efforts are supported by internal and external rate structures that are available upon request.

See below for our other capabilities.

The workhorse of the facility, this instrument includes a full range of SEM detectors, energy dispersive spectroscopy and electron-beam backscatter diffraction, and low vacuum mode. This instrument has a long list of graduate-level internal and industrial external users, across a wide range of research projects. Our undergraduate students also get to use this state-of-the-art system when they take courses in materials characterization, failure analysis, and capstone design.

The workhorse of the facility, this instrument includes a full range of SEM detectors, energy dispersive spectroscopy and electron-beam backscatter diffraction, and low vacuum mode. This instrument has a long list of graduate-level internal and industrial external users, across a wide range of research projects. Our undergraduate students also get to use this state-of-the-art system when they take courses in materials characterization, failure analysis, and capstone design.

Another cornerstone system in a materials characterization lab. We use this instrument extensively to determine the crystal structure metallic and ceramic materials.

Another cornerstone system in a materials characterization lab. We use this instrument extensively to determine the crystal structure metallic and ceramic materials.

For surface-sensitive elemental and chemical analysis, the XPS method is useful and versatile. Irradiation of a material surface by x-rays produces photoelectrons that can be analyzed to provide both compositional and chemical bonding, specific to the top few monolayers of atoms.

For surface-sensitive elemental and chemical analysis, the XPS method is useful and versatile. Irradiation of a material surface by x-rays produces photoelectrons that can be analyzed to provide both compositional and chemical bonding, specific to the top few monolayers of atoms.

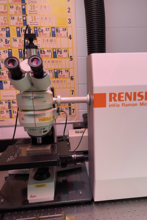

Raman spectroscopy allows the study of the vibrational behavior of molecules. Our Renishaw system pairs a Raman spectroscopy instrument with an optical microscope in order to allow the mapping of molecular properties of polymeric and molecular materials.

Raman spectroscopy allows the study of the vibrational behavior of molecules. Our Renishaw system pairs a Raman spectroscopy instrument with an optical microscope in order to allow the mapping of molecular properties of polymeric and molecular materials.

This automated instrument provides Vickers and Knoop microhardness data.

This automated instrument provides Vickers and Knoop microhardness data.

The classic surface probe methods, atomic force microscopy, and scanning tunneling microscopy allow the imaging of the atoms on a surface down to the nano-scale and, sometimes, down to the atomic level. Useful for the study of nanoparticles and many surfaces at the nano-level.

The classic surface probe methods, atomic force microscopy, and scanning tunneling microscopy allow the imaging of the atoms on a surface down to the nano-scale and, sometimes, down to the atomic level. Useful for the study of nanoparticles and many surfaces at the nano-level.

Finding the right college means finding the right fit. See all that the College of Engineering and Computer Science has to offer by visiting campus.